Corn head

MR-800

Corn head

Adverse conditions

Our upper chain system (optional) achieves continuous feeding even when the corn is down.

Excellent chopping

Its layout provides greater precision and maximum protection with double independent clutch.

High feeding

Its finish and structure optimise corn harvesting and stripping.

Universal adaptation

Thanks to our experience with different manufacturers, it can be adapted to any combine harvester.

Corn head

MR-800

Ensure harvesting success

Combining our experience with the most advanced manufacturing technology, we offer you a header designed by and for professionals.

More than 60 years in the most demanding fields worldwide

The corn head MR-800 model has multiple options for configuration according to the different needs of each client and market. This can be manufactured at any distance between rows from 50 cm, with upper chain on hoods and side augers to harvest in extreme conditions with all the stalks blown down, stalk chopper, metal or plastic hoods, interchangeable rollers with opposing or alternate blades, chain drive in self-lubricated sealed box or gear groups, fixed or folding frame, etc.

Components

Stalk chopper

This design of chopper in the MR 800 Moresil corn header achieves a low requirement of power from the combine.

The stalk chopper is located in an advanced position under the harvesting rolls which allows it to chop the lants since the beginning of harvesting, leaving the stubble uniformly short.

The stalk chopper is equipped with an individual clutch, with which you can achieve a maximum overload protection and guarantees its reliability under all harvesting conditions.

It has a lever on each gearbox to connect or disconnect the stalk chopper at operators convenience. The blades are reversible.

Harvesting rolls

Gearbox-proven reliability with hardened steel gears and bathed in specific lubricant for gear, incorporates a clutch for protection in case of overload, which can be regulated independently from the clutch of the chopper.

The harvesting rollers are fitted with 6 replaceable blades of special anti-wearing material. Also it is offered optionally rolls with blades opposite to each other. They have a lubrication system on the end that doesn’t require maintenance.

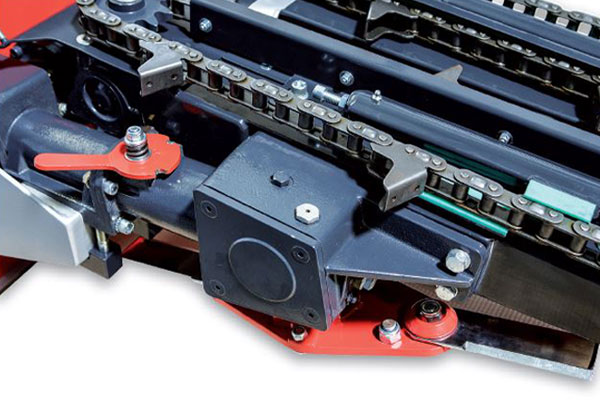

Feeding-chains have a closed ring and they have a special backstop pusher. A new design tensor maintains the correct strain and also allows to change the chains with minimal effort.

Harvesting plates are rounded edge, damage to the ear, made of very hard material. Available hydraulic system for immediate adjustment from cabin.

Reinforced chain drive, adjusted with a self-adjustable tensor in a sealed case bathed in lubricant which ensures a long lasting operation. This system ensures precise adjustment of the revs for each harvester. The headers can be optionally equipped with a group of gears.

Optional Elements

Height Sensor

Row Guidance Sensor

Hydraulic lateral aids (Polyethilene)

Hydraulic or by chain lateral aids (Metal)

Sunflower harvesting Kit

Stalk crusher

Facing blades

Alternate blades

Upper Chain

Upper Feeding Chain

Optional element to harvest corn in extreme conditions, when the plants are laying on the ground can be made easily, getting a continuous supply and high crop yields with minimal loss of grain.

Folding model

Different number of rows and distance between them are available in folding model.

It is a folding system quickly and easily carried out from the combine.

You get an efficient folding for easy visibility from the cockpit.

Our folding model allows to reduce time and cost of travel from one location to another.

The volume of corn production and harvesting worldwide is growing steadily and is expected to continue to increase in the coming years, and for this reason technology is also progressing, designing and creating increasingly advanced machinery for work in the field. Corn harvesting is becoming more and more productive, and this is due to the use of headers specially designed for this agricultural work.

Corn heads

The corn header can be manufactured in different sizes and adapted to numerous combine harvester models on the market, and can be configured in its fixed and folding versions, among other optional elements. With the folding version, we can easily and quickly save time and physical effort for the farmer, since it can be carried out from the combine itself.

Corn heads for sale

At Moresil we offer corn heads for sale that adapt to the different conditions that the farmer will find in his work, being able to face even the adverse conditions that affect corn caused by a derecho storm, since we have the best solution for down corn in the market.

It is advisable when harvesting the grain with the combine harvester to use specialized corn headers for this type of harvesting, so that the harvesting will be faster and more accurate.

If research and development has been invested in designing specific harvesting heads for corn harvesting, it is because its harvesting has some particularities: the corn must be harvested carefully so as not to mistreat or waste it.