Grain Cleaner

M-8

Grain Cleaner

Clean by size & weight

With the sieve and double air extraction systems, the larger and smaller products are extracted together with the lighter pieces of the desired product. Adjustable air and flow rate.

Interchangeable sieves

In order to adapt to the products to be cleaned or selected, the sieves can be replaced quickly and easily from the rear of the machine.

Output

The M-8 grain cleaner-sorter achieves an output of 3,000 kg/h* in sorting mode and up to 15,000 kg/h* in pre-cleaning mode.

Easy maintenance

A simple maintenance comprising the greasing of the moving parts and sieve cleaning system ensures a long service life.

Grain Cleaner

M-8

Multi-purpose machine: Quality cleaning & Easy transport

The set of sieves and air extraction system ensures a quick, simple, and high-quality cleaning. It reaches an output of 3,000 kg/h* in sorting mode and up to 15,000 kg/h in pre-cleaning mode.

Grain Cleaner M-8

The machine M-8 has been designed to comply with the present standards for modern installations in regards to cleanliness and selection of such grains and cereals as wheat, barley, corn, sunflower, rapeseed, vegetables, etc.

It was devised for procuring high yield and thorough removal of impurities reaching percentages well under the official requirements.

It consists of the following main elements:

- Turbine with double air suction with independent control.

- Set of high yield sieves fitted with adjustable lower brushes with continuous self-cleaning movement.

- The sieve compartment is driven by a high frequency movement produced by four eccentric balances accomplishing perfect equilibrium.

Features

| Lenght | 2500 mm |

|---|---|

| Width | 1520 mm |

| Total Height | 3280 mm |

| Grain entrance height | 2660 mm |

| Grain output height | 1070 mm |

| Pre-cleaning | 15 Tm/h* |

| Commercial | 8 Tm/h* |

| Selection | 3 Tm/h* |

| Cribbles area | 3 m2 |

| Power | 5,5 KW |

| Fan | 6000 m3 h |

| Weight | 879 kg |

| Output wheat, density 0,75. Humidity 16%. Impurities 6%. |

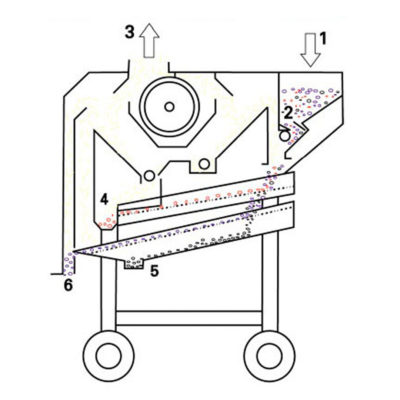

Operation:

1. Grain entry to hopper

2. Control of grain flow to upper sieve

3. Removal of fine impurities and dust

4. Particles of greater size than the grain

5. Thinned-out or broken grains

6. Clean grain

Grain cleaners play a pivotal role in the agricultural industry, ensuring that harvested grains are clean, safe, and ready for processing or direct consumption. By efficiently removing dirt, debris, and other unwanted materials, these machines significantly enhance the quality of the grain. This not only helps in preventing the spread of diseases and pests but also increases the market value of the produce. Moreover, grain cleaners contribute to reducing waste, as they allow for the recovery of grains that might otherwise be discarded due to contamination. Their use leads to a more sustainable and efficient agricultural process, optimizing the yield from each harvest and ensuring that only the highest quality grains make it to the market. For farmers and producers, investing in a reliable grain cleaner is essential for maintaining the integrity of their crops, improving productivity, and meeting the stringent standards of food safety regulations.

Seed cleaner machine

Seed cleaner machines, such as those produced by Moresil, are indispensable tools in modern agriculture, designed to enhance efficiency and productivity across any grain crop. These machines meticulously remove dust, debris, and other unwanted particles from seeds, ensuring that only the cleanest and highest quality seeds are planted. This process is crucial for optimizing germination rates and achieving uniform crop growth, leading to increased yields and profitability. By investing in a versatile and reliable seed cleaner from Moresil, farmers can ensure their crops start from the best possible foundation, regardless of the type of grain being cultivated. This not only supports sustainable farming practices by reducing waste and improving seed usage but also helps in maintaining the health and productivity of the agricultural ecosystem as a whole.

Grain Cleaning Equipment

Grain cleaning equipment manufactured by Moresil stands as a cornerstone in the enhancement of agricultural productivity and quality. This sophisticated machinery is engineered to remove impurities such as dust, straw, and other foreign materials from various grains, ensuring that only the cleanest and highest quality produce reaches the market. The importance of such equipment cannot be overstated, as it directly contributes to the safety and nutritional value of food products. By leveraging Moresil’s grain cleaning technology, farmers and producers can significantly reduce post-harvest losses, increase the shelf life of grains, and meet the rigorous standards set by food safety regulations. Furthermore, clean grains mean better market prices and consumer satisfaction, which in turn drives the economic viability of agricultural ventures. Moresil’s commitment to innovation in grain cleaning equipment underscores the company’s role in supporting a sustainable and prosperous agricultural industry.